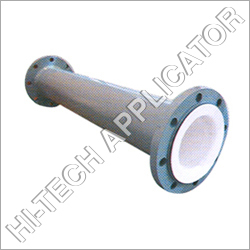

Lined Pipe

Product Details:

- Flexibility Rigid

- Diameter 25 mm to 600 mm

- Sealing Type PTFE Gasket

- Connection Type Flanged / Welded

- Coating Type Epoxy / Painted

- Bend Radius Defined by pipe diameter

- Tolerance 1.5 mm

- Click to view more

X

Lined Pipe Price And Quantity

- Superior

- Hydrostatic and Spark Test on lining

- PTFE is flame retardant

- 1 Piece

- 2.16 g/cm³ (PTFE)

- Low

- Smooth (for reduced friction and chemical retention)

- Bubble Wrap, Wooden Box

- Glossy / Matt (as per specification)

- ANSI B16.5 / DIN PN10, PN16

- High

- Extrusion and Lining Bonding

- Excellent due to PTFE lining

Lined Pipe Product Specifications

- >250 MPa (Steel Pipe)

- 1.5 mm

- Black / Blue / Custom

- Flanged / Welded

- Defined by pipe diameter

- >20 MPa (PTFE Lining)

- Chemical, Pharmaceutical, Water Treatment, Petrochemical Industries

- Lined Pipe

- Up to 6 meters

- Chemical Transport, Corrosive Fluid Handling

- Carbon Steel with PTFE (Polytetrafluoroethylene) Lining

- 25 mm to 600 mm

- up to 16 bar

- Rigid

- Round

- 25 mm to 600 mm

- ASTM F1545 / DIN 2848

- A106/A53 (base pipe), Virgin PTFE (lining)

- Painted / Epoxy Coated

- Epoxy / Painted

- Flanged / Welded

- Cylindrical

- PTFE Gasket

- Superior

- Hydrostatic and Spark Test on lining

- PTFE is flame retardant

- 1 Piece

- 2.16 g/cm³ (PTFE)

- Low

- Smooth (for reduced friction and chemical retention)

- Bubble Wrap, Wooden Box

- Glossy / Matt (as per specification)

- ANSI B16.5 / DIN PN10, PN16

- High

- Extrusion and Lining Bonding

- Excellent due to PTFE lining

Product Description

We are widely recognized as foremost organizations, which are engaged in manufacturing, exporting and supplying world class assortment of Lined Pipes. These pipes are manufactured using high grade material and progressive technology in adherence with the set industry norms. Available in various specifications, our offered Lined Pipes are highly praised by clients for their various unique features such as easy installation, smooth finish and optimum quality. Further, our clients can avail these pipes from us at market leading prices.

Housing Material Options

- PIPE : 1. SEAMLESS CS ASTM A106 GR.B, SCH.-40, 2. ASTM A312 TP 304, SCH.-40

- FLANGE : 1. IS 2062 / ASTM A105, 2. ASTM A351 GR. CF8

Lining Material Options

- PFA - ASTM D 3307

- FEP - ASTM D 2116

- ETFE - ASTM D 3159

- PVDF - ASTM D 3322

- PP - ASTM D 4101

- HDPE

Dimensional Data

|

ANSI #150 Flanged |

||||||

|

SIZE |

A (mm) |

C(mm) |

H(mm) |

S (MIN.) (mm) |

Approx Weight (Kg) |

|

|

FOR 1 Mtr. |

Additional Kg./Mtr. |

|||||

|

DN25-1 |

20.5 |

51 |

2.3 |

3.0 |

4.69 |

2.95 |

|

DN40-1 1/2 |

33.5 |

73 |

3.0 |

3.25 |

7.92 |

4.97 |

|

DN50-2 |

45.5 |

92 |

3.0 |

3.25 |

11.04 |

6.63 |

|

DN80-3 |

70.9 |

127 |

3.5 |

4.0 |

21.96 |

13.74 |

|

DN100-4 |

94 |

157 |

3.5 |

4.5-5.0 |

30.52 |

19.4 |

|

DN150-6 |

144.1 |

216 |

4.5 |

6.0-6.5 |

On Request |

On Request |

|

DN200-8 |

190.7 |

270 |

5.0 |

Consult Factory |

On Request |

On Request |

|

Lined Pipe Vacuum Resistance (in inch of Mercury) |

||||||

|

Material |

Temp. |

25 NB |

40 NB |

50 NB |

80 NB 100 NB |

|

|

|

21c |

Full |

Full |

Full |

Full |

Full |

|

PTFE |

100c |

Full |

Full |

Full |

Full |

Full |

|

|

175c |

Full |

Full |

Full |

Full |

Full |

|

|

21c |

Full |

Full |

Full |

Full |

Full |

|

PVDF |

85c |

Full |

Full |

Full |

Full |

Full |

|

|

135c |

Full |

Full |

Full |

Full |

Full |

|

PP |

21c |

Full |

Full |

Full |

Full |

Full |

|

|

95c |

Full |

Full |

Full |

Full |

Full |

|

HDPE |

21c |

Full |

Full |

Full |

Full |

Full |

|

|

65c |

Full |

Full |

Full |

Full |

Full |

- Consult Hi-Tech Applicator for vacuum services. Special Heavy Duty PTFE Liners vailable for full vacuum. Details can be provided on request. Other Flange Drillings like, DIN 2632 / 2633 , BS 10 Table D, E or F are also available on request.

- Max. Length available : 3 Mtr.

- Tolerance : 3.5mm (0 to 1 Mtr.) and 5.0mm (1 to 3 Mtr.)

- Clear ID for HDPE/PP Lined Pipes (DN/ID): 25/18 , 40/32 , 50/42 , 65/57 , 80/67

Superior Corrosion and Chemical Protection

The PTFE lining inside each pipe acts as a protective barrier against highly corrosive and reactive chemicals, ensuring long-term durability even with aggressive substances. This design guarantees minimal permeation and maximum safety for applications in chemical processing, water treatment, and pharmaceuticals.

Precision Manufacturing and Rigorous Quality Control

Our pipes are fabricated through advanced extrusion and bonding techniques and are thoroughly inspected with hydrostatic and spark tests. Each piece meets strict tolerances of 1.5 mm and is offered with customizable finishes and colors for specific project requirements, ensuring both reliability and consistency.

Versatile Applications and Custom Configurations

Compatible with ANSI and DIN flange standards and available in both flanged and welded connections, our lined pipes provide flexible integration for various systems. Whether for chemical, petrochemical, or pharmaceutical industries, these pipes guarantee optimal performance and easy installation, with a minimum order quantity of just one piece.

FAQs of Lined Pipe:

Q: How does the PTFE lining enhance the corrosion resistance of these pipes?

A: The virgin PTFE lining forms a seamless internal barrier that is inert to most chemicals, preventing corrosion and oxidation of the underlying steel, making these pipes highly reliable for transporting aggressive or corrosive fluids.Q: What inspection methods are used to ensure the quality of the lined pipes?

A: Every pipe undergoes hydrostatic testing for pressure integrity and a spark test to confirm continuous, defect-free PTFE lining. These procedures ensure that no leaks or faults are present before delivery.Q: When should I choose a PTFE lined pipe over a conventional steel or plastic pipe?

A: PTFE lined pipes are recommended when chemical compatibility, corrosion resistance, and low permeability are crucial, such as in chemical transport systems and environments dealing with aggressive fluids that could damage ordinary steel or plastic pipes.Q: Where are these lined pipes commonly used?

A: These pipes are typically used in chemical processing plants, pharmaceutical manufacturing, petrochemical industries, and water treatment facilities where durability against hazardous chemicals and fluids is required.Q: What is the process for manufacturing the PTFE lined pipes?

A: The pipes are produced using a combination of steel pipe extrusion, followed by precision lining with PTFE through bonding techniques. The finished pipe then receives painting or epoxy coating as specified, with strict dimensional and quality checks at each stage.Q: What are the main benefits of using a PTFE lined pipe for fluid handling?

A: Key benefits include exceptional chemical and corrosion resistance, smooth internal surfaces that minimize product retention and friction, high electrical insulation, low permeability, and compliance with international standards for safety and performance.Q: How are the pipes packed and shipped to ensure safety?

A: Each pipe is wrapped in bubble wrap and packed in sturdy wooden boxes to protect against mechanical damage during transit. This ensures that the product arrives in perfect condition, ready for installation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese